New Nanofiber Production Platform

Nanofibers fabrication from an immersion rotary jet-spinning system

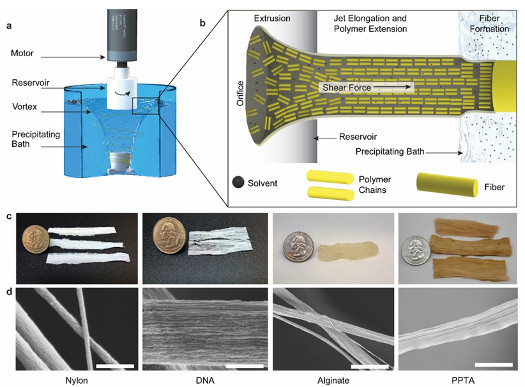

Nanofiber production platforms are limited by their dependency on volatile carrier solvents or the use of high voltages. These limitations make them inadequate for producing nanofibers based on polymers such as aramids (e.g., Kevlar®) and biopolymers (e.g., DNA) that require dissolution in non-volatile, high surface tension solvents. To address these issues, Kit Parker developed an immersion Rotary Jet-Spinning (iRJS) system (a) that employs centrifugal forces to extrude a polymer solution through an air gap and into a precipitation bath (b). This ensures that nanofiber solidification occurs in liquid, minimizing surface tension instabilities, the primary cause of jet breakup and fiber defects. They fabricated defect-free Kevlar®, Nylon, DNA, and alginate-based nanofibers (c and d). By controlling the spinning parameters they fabricated blended alginate-bioprotein nanofibers for tissue engineering and tuned Kevlar® nanofiber crystallinity. At a production rate of ~60g/h per orifice, this extensive range of materials was achieved without limiting platform scalability.

David A. Weitz (Physics and Applied Physics)

Harvard MRSEC (DMR-1420570)