Combining Microfluidics and 3D Printing

to Fabricate Droplets in Droplets

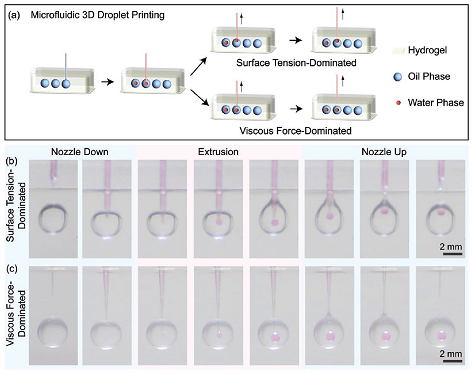

By combining microfluidic and 3D printing, Weitz has established a new droplet printing method that enables precise control over droplet size, geometry, and composition. In this process, oil droplets are first printed in a hydrogel support bath, which is a transparent and shear thinning material. Next, the nozzle is reinserted through the matrix to embed a smaller water-based droplet within the core of each oil droplet. Detailed studies of the printing process revealed that drop detachment from the nozzle during printing depends strongly on the middle oil viscosity and density, the inner droplet size, and the nozzle diameter. The printed particles may find potential applications as delivery vehicles for myriad functional and biological cargos.

Publication:

Chen, L., Y. Xiao, Q. Wu, X Yan, P. Zhao, J. Ruan, J. Shan, D. Chen, D.A. Weitz, and F. Ye, "Emulsion designer using microfluidic three‐dimensional droplet printing in droplet," Small 17 (39), 2102579 (2021) ![]()

![]()

David A. Weitz (Physics & Applied Physics)

2020-2021 Harvard MRSEC (DMR-1420570)